Pillar drill bottle capper

I bottle all of my homebrew. Bottling is one of the more tedious tasks of brewing, and consists of different steps; filling the bottle, capping it, labelling and cleaning. The easier and faster I can make these tasks, the better. I have a pretty good work-flow for filling, labelling and cleaning bottles, but capping needed some improvement.

I bottle all of my homebrew. Bottling is one of the more tedious tasks of brewing, and consists of different steps; filling the bottle, capping it, labelling and cleaning. The easier and faster I can make these tasks, the better. I have a pretty good work-flow for filling, labelling and cleaning bottles, but capping needed some improvement.

I needed a very sturdy bottle capper, and decided to give my pillar drill a second purpose. I turned a capping tool on my lathe, sized to fit in my drill’s drill head. On the bed of the drill press I fashioned a bottle support. This support ensure that the bottle is inserted at the right height, and a semi-circular cut-out positions it directly under the capping tool.

The capping tool sits a few mm above the bottle. This tight spacing limits the amount of travel of the head before full capping is reached, and quickly secures the cap before it can fall off the bottle.

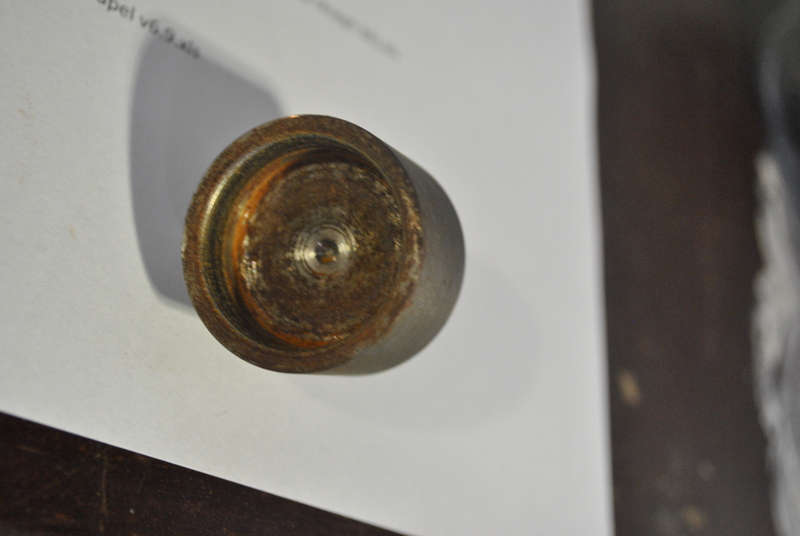

The capper was turned from left-over steel bar stock. Since it has no rust protection applied, it starts to rust. I find this is not a problem, every once in a while I spin up the drill and remove the rust with a piece of 400 grit sandpaper.

The inside rim of the capper is slightly conical. This ensures a gradual crimping of the cap. When the cap reaches the end of the capper, the bottle is help by the capper until it is removed by hand.

The top of the capper fits in the drill head.